We have already told you about current recycling technologies in the textile industry, their limits and potential, but today we want to go further and tell you concretely about a very near future: what will the textile industry be like in 2030? Will recycling triumph? What challenges will it face? And what benefits will it bring? Thanks to McKinsey & Company’s analysis, we are here to provide you with a reliable and detailed scenario.

Textile industry and recycling in Europe today

Today, each person in Europe produces on average more than 15 kg of textile waste per year.

85% of the total textile waste consists of discarded clothes and household textiles.

And what does that mean? Landfill or incineration, pollution and waste.

But according to McKinsey&Co, a significant breakthrough is perhaps in store for us. There are indeed several ways to solve the problem, such as:

- reducing overproduction and overconsumption

- extending the durability of products

- designing products with higher circularity.

And then there is one, in particular, that is very effective, sustainable and also scalable. It is fibre-to-fibre recycling, i.e. the transformation of waste into new fibre, which is then used to create new clothes or new textile products. This practice is characterized by a strong innovative drive, which has already led to the consolidation of some technologies, such as the mechanical recycling of pure cotton, and the development of others that will soon be commercialized, such as the chemical recycling of polyester.

McKinsey&Co estimates that, by the time these technologies reach full maturity, it will be possible to recycle by the fibre-to-fibre method about 70% of the total textile waste. Quite a difference from the current 1%. But why are we in this situation today?

What are the challenges of textile recycling?

The first one is collection: European percentages are around 30-35% of total textile waste recovered, while a large percentage is exported outside Europe without even being sorted. And here it is mainly a matter of changing habits and legal obligations.

As you already know if you have read Textile recycling: technologies and perspectives, another problem concerns material composition. Most recycling technologies, indeed, have strict requirements concerning the composition and purity of input materials, and have difficulties especially with fibre blends, which they are not yet able to separate and recycle.

Then there are complications related to the pre-processing of material destined for recycling: the removal of buttons, zips, sequins and various applications is currently done manually or with systems that are still too undeveloped. And the same goes for the selection and pre-processing of fibres.

To reach the full maturity mentioned above, moreover, costs must be reduced and the quality of production improved.

But according to McKinsey&Co’s analysis all these knots can be untied (we will tell you how in a moment), and it will then be possible to achieve a fibre-to-fibre recycling rate ranging from 18 to 26%, based on an expected collection rate of 50% in the first case (base-case scenario), 80% in the second (upside-case scenario).

But how can these textile recycling rates be achieved in 2030? And which economic, environmental and social results would it bring?

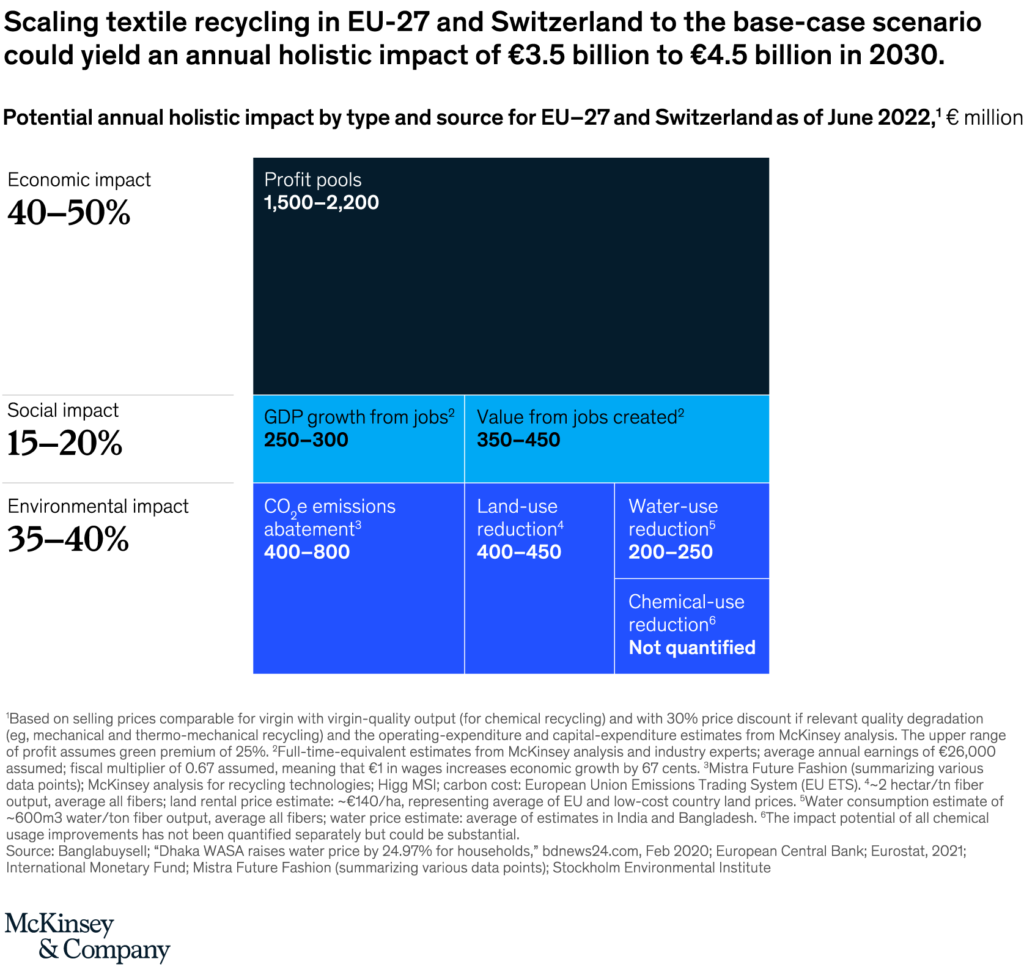

Investments are clearly needed. McKinsey&Co calculates that the amount required to scale up adequately these technologies is between 6 and 7 billion euros, which is to be spread over the entire value chain (collection, sorting, recycling). Thanks to this operation, the industry would become autonomous and profitable, generating a profit of somewhere between 1.5 and 2.2 billion euros. But the value generated through a textile industry based on recycling could even go beyond this estimate, as a new and valuable (secondary) raw material would be created, which would enable the intensification of clothing production in Europe.

And these are only the direct economic benefits, but McKinsey&Co goes deep into the matter and makes a report that also quantifies other factors, such as: new jobs, whose expected growth for the base-case scenario is 15,000, CO2 emissions, which would be reduced by 4 million tonnes, and the use of water and lands, which would be much lower. Considering all these social and environmental benefits and the resulting economic savings, the textile industry would achieve a total annual impact of between 3.5 and 4.5 billion euro by 2030, with an annual return on investment of between 55% and 70%.

The 5 keys of success for a circular textile industry in 2030

This prosperous scenario, we said, is plausible, but it will certainly not happen by itself, miraculously. Instead, it is necessary to act, and to start doing so now. How?

Here are what McKinsey&Co consider to be the 5 courageous actions that will make a difference:

- scalability – the textile recycling value chain cannot operate on a small scale: for technologies to work on a large scale, sufficient raw materials must also be available; therefore, the industry must achieve high participation in all stages of the value chain

- collaboration – companies, investors and institutions need to talk to each other and find immediate solutions to overcome existing obstacles, and they need to do this by creating a highly operational collaboration that is without precedent

- transition funding – in order to bring the industry to self-sustainability and profitability, funding must be made in the short term: initiatives such as Extended Producer Responsibility grants, green awards, both public and private solutions will be key to achieving the goal

- investment – as the hoped-for circular model is very different from the linear model currently in use, many parts of the value chain have to be built almost from scratch and this requires the use of substantial capital; it would be the private players who would have to take the initiative here, bearing in mind that the risk would be offset by the economic value produced

- push from the public sector – on the other hand, leaders of public institutions need to contribute in making recycling essential in the textile industry: increasing collection rates, limiting the export of unsorted textile waste, engaging in demand stimulation, creating operational and integrated plans for greater circularity and other measures must necessarily be among the short-term goals of States and supranational organizations.

Thus, we can conclude from this report that recycling in the textile sector can still triumph by 2030, that a sustainable future is still possible. And not only that, it is a rosy and competitive future, but tied to urgent and courageous actions that require the commitment of everyone: companies, institutions, people.

So what can you do?

Contact us, we will explain how we can collaborate ➡️ info@nazena.com

CONSULTATIONS:

Scaling textile recycling in Europe – turning waste into value

Saskia Hedric, Jonatan Janmark, Moa Strand, Nikolai Langguth, Karl-Hendrik Magnus

McKinsey & Company, July 14, 2022